Shanti Air Handling (AH) Division was established in 2006 to serve the needs of industries requiring Air Pollution Control System. We manufacture Pollution Control Equipment’s , right from Single cyclone dust collection systems, Multi Cone Cyclone Dust Collectors , Pulse Jet Bag filter, Reverse Air Bag House, Wet Settling Chambers, Wet Scrubber .We intend to be ” One Stop Shop ” our client’s requirements right from Boilers to balance of plants including pollution control equipment, which in today’s scenario is become utmost importance.

Types of Pollution Control Equipment:

• Pulse Jet bag Filters

• Multi Cone Dust Collectors

• Wet Scrubbers

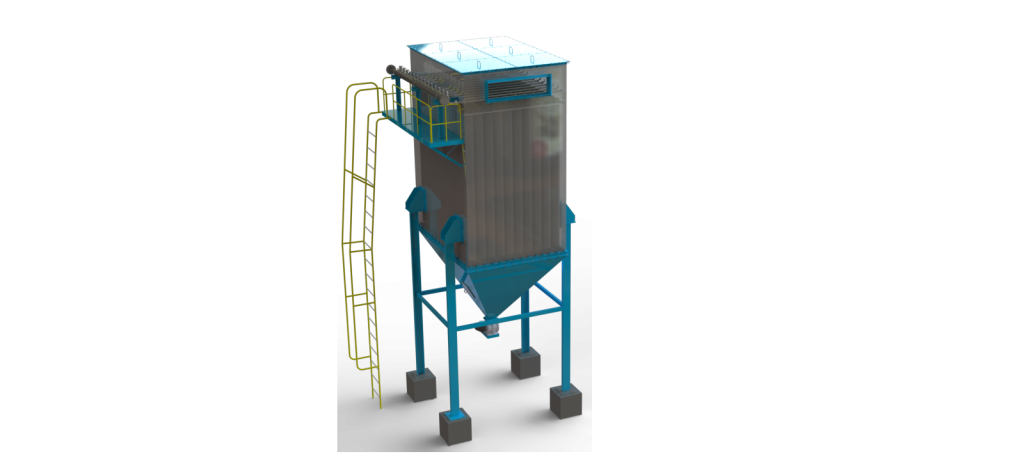

Pulse Jet Bag Filter

Shanti pulse jet bag filters are one of the most efficient and cost effective solution for pollution control emmiting of Boilers . Its a online pulse jet bag filter, where the dust /ash from the industrial boilers gets trapped in specially installed high temperature bags through which flue gas is allowed to pass. for reliability and durability.

Such dust and ash is cleaned row by row and this sequence is controlled through a controller. The dust particulars are deposited at the outer surface of the bag and are removed in a pre-timed cycle by a pulse jet of high pressure air sourced from an air compressor. This highly advanced process streamlines the dust particulars into the RAV with the help of hopper and ensures that only clean air moves out from the center of the bag & escapes out of flue gas outlet. Our bag filters are designed with optimal air to cloth ratio ensuring efficient performance.

Shanti uses superior raw materials like high temperature fiber glass bags

Single Cyclone Dust Collectors

Shanti Single Cyclone Dust Collectors are designed on Vertex separation science . The dust collectors are designed so to provide cyclonic and rotation effect to separate dense particulate matter in the flue gases . A high circulating air flow is allowed to travel in a helical pattern from the top of the dust collector . This creates higher inertia and follow tight curve this ideal rotation effect will force the dense particulate mater to settle at the bottom of the cone , which in turn is removed manually or mechanically. Single Cone dust collectors are more suitable for biomass fuels like Wood , Briquettes only .

Mechanical Cyclone Dust Collectors

Shanti Single Cyclone Dust Collectors are designed on Vertex separation science . The dust collectors are designed so to provide cyclonic and rotation effect to separate dense particulate matter in the flue gases . A high circulating air flow is allowed to travel in a helical pattern from the top of the dust collector . This creates higher inertia and follow tight curve this ideal rotation effect will force the dense particulate mater to settle at the bottom of the cone , which in turn is removed manually or mechanically. Single Cone dust collectors are more suitable for biomass fuels like Wood , Briquettes only .

Capacities

All Boiler capacities

Features

- Ideally sized ensures efficiency , reliability

- Use of Cast Iron Cones & Vanes for very long life for certain abrasive fuels

- Negligible maintenance downtime

How Efficient are Cyclone Collectors?

The particle collection efficiency of a cyclone depends on a number of factors, including the dimensions (Length and Diameter) or cyclone, the inlet gas velocity, the particle size and the dust concentration in the gas stream. Collection efficiency tends to increase when inlet gas velocity increases and when particles size and dust concentration increases. Also, smaller cyclones are usually more efficient than are larger cyclones. Large-diameter cyclones are most effective in removing relatively large particles from a gas stream.