Boiler preservation is required when boiler is out of service or in shutdown condition for a long period to protect boilers internal surface from corrosion and atmospheric oxygen.

Corrosion effect on the Boiler surface

PREVENTIVE METHODES

There are two types of boiler preservation methods each of them is used in specific conditions.

- Wet preservation of boiler

- Dry preservation of boiler

Boiler preservation through nitrogen method is also used in power plant boilers.

These methods are designed to limit corrosion caused by the normal range of boiler and atmospheric contaminants.

Wet Preservation of boiler:

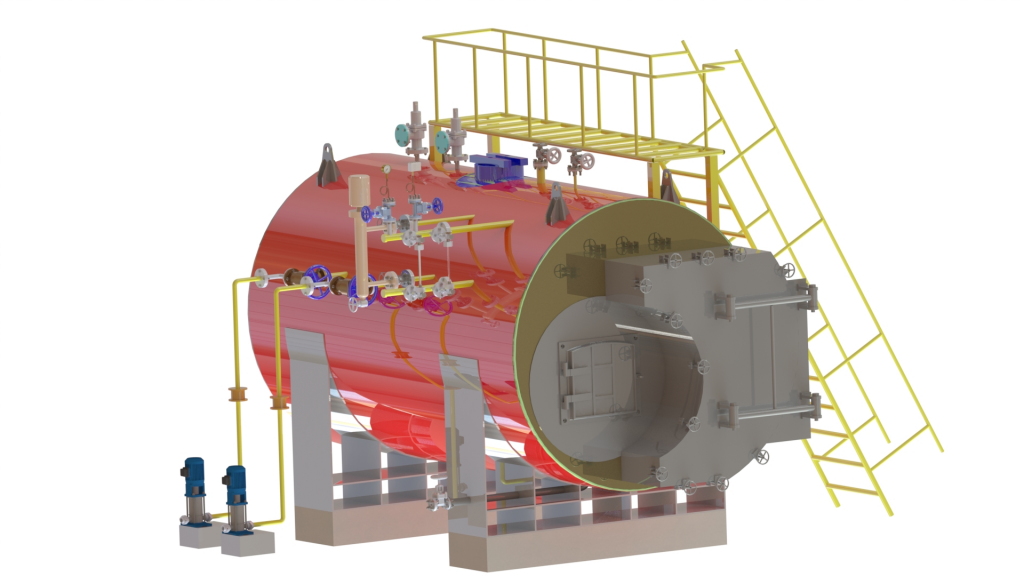

If Boilers are required in stand by condition for sudden and quick demands of steam are preserved by the wet method. This method is also used for large boiler units which are difficult to drain.

Total Boiler pressure parts economizer, steam drum, water walls, super heater tube are filled with feed water having high concentration of Hydrazine (200 PPM). Such high concentration of hydrazine ensures, there is no dissolved oxygen available in feed water. Boiler is kept under pressure, so that atmospheric air can’t enter in to Boiler pressure parts.

Dry Preservation of boiler

This method is used when boiler is required to be shut down for a long period. Dry preservation requires the removal of all water and the moisture of air to maintain a relative humidity less than 50%, and preferably less than 40%. This prevents corrosion by hygroscopic salts. Dry-air (dehumidified) storage is highly effective, and its continued effectiveness is easy to monitor. Dry preservation allows easy and safe access for maintenance, with no potential for suffocation and no exposure to toxic chemicals.

Benefits of Preservation of Boiler

The life of the Boiler will increase.

Increase in the availability time of Boiler.

Maintenance cost will decrease.

We can avoid the descaling and chemical cleaning of the Boiler after longer shutdowns.